Customize Your Workwear with Precision and Style!

At Workwear Works, we understand that your workwear is a reflection of your brand and professionalism. That’s why we offer a range of top-notch personalisation options, including embroidery and t shirt printing, to help you stand out in the workplace

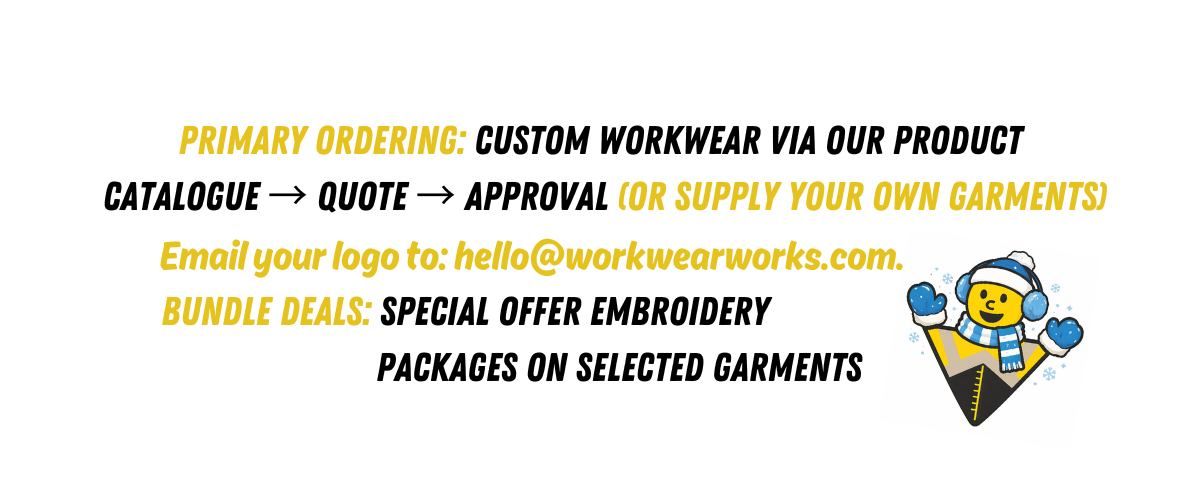

Table of Contents

1. Embroidery:

Elevate Your Workwear with Elegant Embroidery!

At Workwear Works, we believe that every stitch counts when it comes to creating workwear that embodies professionalism and style. Enter the world of embroidery, where craftsmanship and sophistication meet.

Why Choose Embroidery?

Embroidery is a timeless choice for adding a touch of class to your workwear. Here’s why it’s a top pick for many:

1. Timeless Elegance: Embroidery exudes a timeless and elegant look that never goes out of style. It adds a touch of sophistication and professionalism to your work attire.

2. Durability Guaranteed: Our embroidery is built to last. The precision stitching ensures your logo or design remains intact through countless washes and long workdays.

3. Versatility Meets Precision: Whether it’s your company logo, employee names, or intricate artwork, embroidery brings your designs to life with unmatched precision and attention to detail.

Why Opt for Embroidery for Your Workwear?

– Professional Appearance: Perfect for creating a polished, corporate look.

– Durability: Withstands daily wear and tear, making it ideal for work environments.

– Customization: Tailor your workwear with precision embroidery that reflects your brand identity.

Choose the enduring elegance of embroidery from Julianas Custom Designs. We take pride in the artistry of our work, ensuring every stitch speaks volumes about your brand.

2. DTF Printing (Direct-to-Film Printing):

Experience Vibrant Customization with DTF Printing!

At Workwear Works, we’re all about making your workwear customization journey exciting and colorful. Introducing our cutting-edge DTF (Direct-to-Film) printing option, perfect for bringing your designs to life in the most vibrant way possible!

What is DTF Printing?

DTF printing is a revolutionary technique that allows us to reproduce your artwork or logo with stunning clarity and detail. Here’s why you’ll love it:

Direct-to-Fabric (DTF) printing is indeed known for its ability to bond with fabric and stretch along with it, which can be a significant advantage over traditional screen printing in certain situations. Here are some key benefits of DTF printing:

- Flexibility and Stretch: DTF printing allows the ink to penetrate and bond with the fabric fibers, creating a flexible and stretchable print. This makes it an excellent choice for apparel items like t-shirts, activewear, and sportswear, where the fabric’s stretch properties are crucial.

- No Cracking: Unlike some traditional printing methods, such as screen printing, DTF printing is less prone to cracking or peeling when the fabric stretches or undergoes repeated movements. This durability makes it ideal for garments that require longevity.

- Vibrant Colors: DTF printing can produce vibrant and full-color prints with high levels of detail. It allows for the printing of intricate designs and complex artwork with a wide range of colors.

- Versatility: DTF printing can be used on various fabric types, including cotton, polyester, blends, and even dark-colored fabrics. This versatility makes it suitable for a broad range of applications.

- Photo-Realistic Printing: DTF printing can achieve photo-realistic quality, making it an excellent choice for custom apparel with highly detailed images, photographs, or complex graphics.

- Soft Hand Feel: DTF prints typically have a soft and comfortable feel on the fabric, which enhances the overall comfort of the garment.

It’s important to note that while DTF printing offers many advantages, the quality of the final print can still depend on various factors, including the type of fabric used, the quality of the DTF printer and inks, and the expertise of the printing service. Additionally, DTF printing may not be suitable for all applications, and other methods like screen printing or embroidery may still be preferred for certain projects.

Ultimately, the choice between DTF printing and other printing methods should be based on your specific needs, the type of fabric, the design requirements, and your budget considerations. Consult with us to determine the best printing method for your project.

Why Choose DTF Printing for Your Workwear?

– Captivating Graphics: Ideal for intricate and colorful designs.

– Photograph Reproduction: Perfect for showcasing high-resolution images.

– Long-Lasting Quality: Ensures your workwear maintains its brilliance over time.

– Versatile Applications: Suitable for various industries, from hospitality to fashion.

Elevate your workwear game with DTF printing from Julianas Custom Designs. We take your customization needs seriously and bring your designs to life with precision and style.

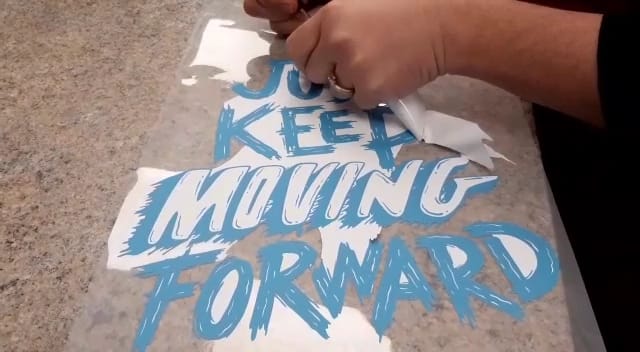

3. Elevate Your Style with Vinyl Print on Clothing

At Workwear Works, we believe that fashion should be an expression of individuality, and our vinyl print on clothing service allows you to do just that. With our cutting-edge technology and a wide range of customization options, you can transform your wardrobe into a canvas of creativity.

Why Choose Vinyl Print on Clothing?

Vinyl printing on clothing offers a plethora of benefits that set it apart from other customization methods:

- Durability: Vinyl prints are highly durable, ensuring that your designs remain sharp and vibrant wash after wash.

- Customization: Express your unique style with fully customized designs, from personal artwork to branding and logos.

- Versatility: Vinyl prints can be applied to a variety of clothing items, including t-shirts, hoodies, jackets, hats, and more.

- Quick Turnaround: Our efficient vinyl printing process ensures quick turnaround times without compromising on quality.

The Art of Personalisation

Our vinyl printing process is all about personalization. Here’s how it works:

- Design Consultation: Collaborate with our experienced design team to bring your vision to life. Whether it’s a one-of-a-kind graphic, a promotional logo, or a special message, we’re here to make it happen.

- Material Selection: Choose from a wide range of vinyl materials, including different colors, finishes, and textures, to create the perfect look and feel for your clothing.

- Precision Printing: Our state-of-the-art equipment ensures that every detail of your design is accurately reproduced, no matter how intricate.

- Professional Application: Our skilled technicians carefully apply the vinyl to your clothing, ensuring a flawless finish that’s both comfortable to wear and long-lasting.

Endless Possibilities

With vinyl print on clothing, there are endless possibilities for personalisation:

- Fashion Statements: Create unique t-shirts, hoodies, and more that showcase your style and personality.

- Branding: Promote your business or organization with branded clothing that makes a lasting impression.

- Events and Special Occasions: Celebrate events and milestones with customized clothing for your team, family, or friends.

- Gifts: Give the gift of personalized clothing for birthdays, weddings, anniversaries, and other special occasions.

4. DTP Heat Transfer for Your Workwear

Introduction:

In the realm of garment customization, DTP Heat Transfer has emerged as a cutting-edge technique, revolutionizing the way we imprint designs onto workwear. This article explores the essence of DTP Heat Transfer and delves into the compelling reasons why choosing this method for your workwear can elevate your brand aesthetic and employee pride.

What is DTP Heat Transfer?

Unveiling the Technology:

DTP Heat Transfer, or Direct Transfer Print using heat transfer, is a contemporary garment printing method that seamlessly fuses technology and design. This process involves transferring a digitally created design onto workwear using a specialized heat transfer paper and a heat press. The result is a vibrant, high-resolution imprint that is both durable and visually striking.

Precision in Design:

With DTP Heat Transfer, intricate and detailed designs find a perfect canvas. Whether it’s company logos, employee names, or specific branding elements, this method captures the nuances with precision, ensuring that your workwear becomes a powerful representation of your brand identity.

Why Choose DTP for Your Workwear?

Professional Aesthetics:

One of the key reasons to opt for DTP Heat Transfer in workwear customization is the professional aesthetics it offers. The method provides a sharp, clean finish, making it ideal for corporate branding. Your employees will proudly wear workwear that reflects a polished and cohesive look, leaving a lasting impression on clients and customers.

Versatility Across Fabrics:

Workwear comes in various materials, and DTP Heat Transfer proves to be versatile across the spectrum. Whether your uniforms are made of cotton, polyester blends, or a combination of materials, DTP ensures a seamless application, maintaining the integrity of the fabric while delivering vibrant prints.

Durability for the Long Haul:

In the demanding environment of workwear, durability is non-negotiable. DTP Heat Transfer excels in this aspect, offering prints that withstand the rigors of everyday wear, washing, and exposure to the elements. Your brand message stays intact, ensuring a lasting and consistent representation.

Customization without Compromise:

Every business is unique, and DTP Heat Transfer allows for unparalleled customization without compromising on quality. From intricate designs to specific color matching, this method empowers businesses to create workwear that aligns with their brand vision and values.

Cost-Effective for Any Scale:

Whether you’re outfitting a small team or an entire workforce, DTP Heat Transfer proves to be cost-effective. It eliminates the need for large minimum orders, allowing businesses of all sizes to invest in high-quality, custom workwear without breaking the bank.

Conclusion:

In the dynamic landscape of workwear customization, DTP Heat Transfer emerges as a game-changer, combining innovation with practicality. Elevate your brand image, foster employee pride, and make a lasting impression with workwear that goes beyond functionality – it becomes a canvas for your brand story.

Choose DTP Heat Transfer, where technology meets style, and transform your workwear into a powerful statement of professionalism and individuality. Experience the seamless fusion of design and durability, and watch as your brand leaves an indelible mark in the minds of clients, customers, and employees alike.

Here’s a breakdown of which customization method is ideal for different types of fabric:

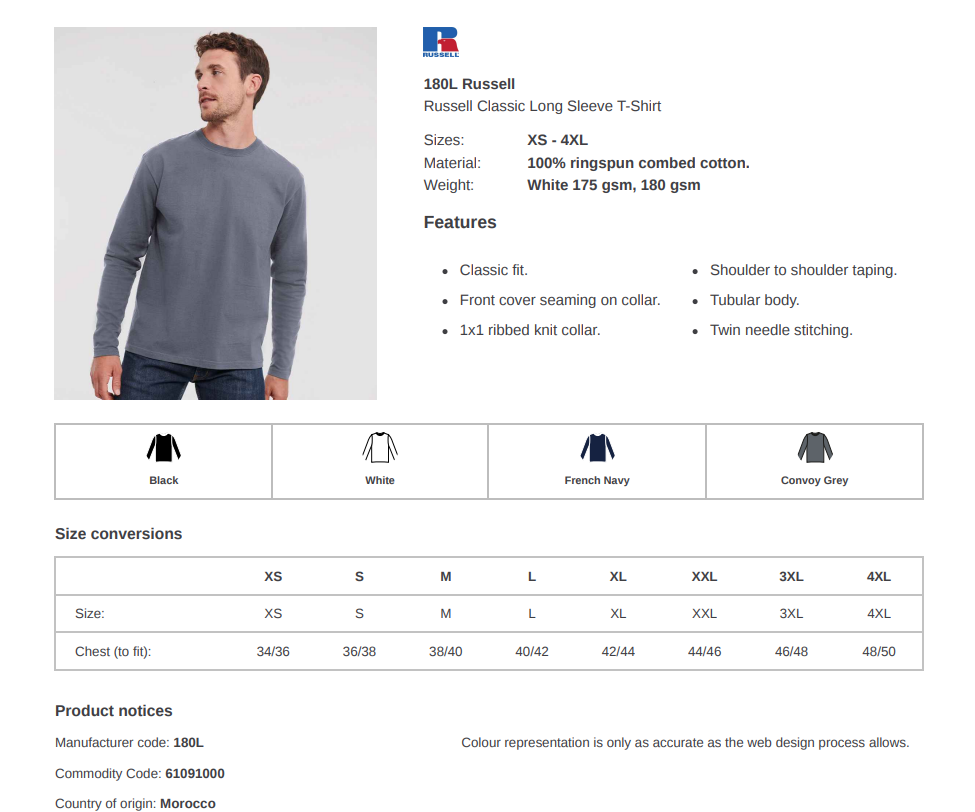

Embroidery:

– Cotton: Embroidery works exceptionally well on cotton fabric due to its natural fibers and durability.

The minimum weight or fabric density (measured in grams per square meter, GSM) required for high-quality embroidery can vary depending on several factors, including the complexity of the embroidery design, the type of fabric, and the desired outcome. While a minimum of 175 GSM is a reasonable starting point for many types of fabric, it’s essential to consider the following factors:

- Fabric Type: Different fabrics have varying levels of thickness and density. Some fabrics, like heavy cotton or denim, can support high-quality embroidery at lower GSM values. Lighter fabrics, such as sheer organza or lightweight jersey, may require a higher GSM to prevent puckering or distortion during embroidery.

- Embroidery Design Complexity: Highly intricate or dense embroidery designs may require a sturdier fabric to support the weight of the stitches and maintain the design’s integrity. In such cases, you might need a fabric with a higher GSM.

- Intended Use: Consider how the embroidered item will be used. For items like apparel or bags that will be subjected to frequent wear and washing, a higher GSM fabric might be preferred for durability.

– Denim: The sturdy nature of denim makes it a suitable canvas for embroidery.

– Twill: Twill fabrics, such as those used for work pants or jackets, are commonly embroidered.

Best Use Cases:

– Cotton polo shirts: Ideal for a professional and polished look.

– Denim jackets or jeans: Adds a touch of style and personalization.

– Work uniforms made from twill fabric: Offers durability and branding.

In summary, while 175 GSM can be suitable for many embroidery projects, it’s not a one-size-fits-all requirement. Consider the unique characteristics of your project and communicate with us to determine the best fabric weight for achieving high-quality results.

DTF (Direct-to-Film) Printing:

Ideal Fabric Types:

– Polyester: DTF printing adheres well to polyester fabrics, creating vibrant and detailed designs.

– Blends: Works on fabric blends with a significant polyester component, such as poly-cotton blends.

Best Use Cases:

– Polyester sportswear: Excellent for team uniforms with colorful graphics.

– Performance apparel: Ideal for moisture-wicking shirts used in sports or fitness.

– Poly-cotton blend T-shirts: Allows for detailed artwork and vibrant colors.

Unleashing Creativity: Why DTP is Ideal for Different Types of Fabric

Introduction:

In the dynamic world of garment decoration, the choice of printing method plays a pivotal role in achieving vibrant, detailed designs. Desktop Publishing (DTP), particularly in the form of Direct Transfer Print using heat transfer, stands out as an ideal solution for a myriad of fabric types. This article explores the versatility of DTP, shedding light on why it’s the go-to choice for bringing creative visions to life on various textiles.

The Fabric Spectrum: Understanding DTP’s Versatility

Organic Cotton:

For those inclined towards sustainable and eco-friendly fashion, organic cotton is a popular choice. DTP proves to be a perfect match for this fabric, seamlessly transferring intricate designs onto the natural fibers. The process retains the breathability and softness of organic cotton while offering a vivid canvas for artistic expression.

Polyester Blends:

In the realm of activewear and performance garments, polyester blends reign supreme. DTP effortlessly adheres to these synthetic fibers, providing a durable and flexible print solution. The method ensures that the stretch and moisture-wicking properties of polyester blends remain intact, making it an ideal choice for sports and outdoor apparel.

Luxurious Silks and Satins:

For those seeking to add a touch of luxury to their garments, DTP stands up to the challenge of embellishing delicate fabrics like silk and satin. The process ensures that the intricate designs are applied with precision, enhancing the opulence of these materials without compromising their inherent elegance.

Linen’s Breathable Canvas:

Linen, known for its breathability and comfort, finds a compatible partner in DTP. Whether it’s a relaxed summer shirt or a stylish tote bag, DTP brings designs to life on linen with a crisp and vibrant finish. The method preserves the natural texture of linen while offering a personalized touch to each piece.

Stretchy Spandex and Lycra:

Activewear and garments requiring stretch demand a printing method that can withstand constant movement. DTP rises to the occasion on fabrics like spandex and Lycra, ensuring that the prints retain their vibrancy even in high-stretch areas. The result is activewear that seamlessly combines functionality and style.

Why DTP Excels Across Fabrics:

Full-Color Freedom:

DTP’s ability to reproduce full-color designs makes it a versatile choice for various fabrics. Whether it’s the earthy tones of cotton or the vibrant hues of synthetic blends, DTP captures the essence of the design with unparalleled precision.

Durability Across Wear and Wash:

Garments face the dual challenges of wear and frequent washing. DTP’s durability ensures that prints remain sharp and vibrant even after repeated cycles, making it a practical choice for everyday clothing and uniforms.

Adaptable to Different Textures:

Fabrics come with distinct textures, and DTP adapts seamlessly. From the smooth finish of satin to the textured weave of denim, the method accentuates the unique characteristics of each fabric, resulting in visually appealing and tactile designs.

Vinyl Print:

Ideal Fabric Types:

Vinyl printing is a versatile method that can be applied to a variety of fabric types. However, the best fabrics for vinyl printing are typically those that are smooth, durable, and have minimal texture. Here are some fabric types that work well with vinyl printing:

- Cotton: Cotton is a popular choice for vinyl printing. It’s smooth, breathable, and offers a flat surface for vinyl to adhere to. Cotton t-shirts and hoodies are commonly used for vinyl printing.

- Polyester: Polyester is another suitable option, especially for sportswear and performance apparel. It’s lightweight, moisture-wicking, and provides a smooth surface for vinyl application.

- Blends: Fabric blends, such as cotton-polyester blends, can offer the best of both worlds. They combine the comfort of cotton with the durability and moisture-wicking properties of polyester.

- Canvas: Canvas fabrics are thicker and more rugged, making them suitable for vinyl printing on items like tote bags, aprons, and jackets.

- Fleece: Fleece materials, such as polar fleece or microfleece, are soft and comfortable. They can be used for vinyl printing on jackets, blankets, and sweatshirts.

- Nylon: Nylon fabrics are often used for outerwear, bags, and accessories. They are durable and offer a smooth surface for vinyl application.

- Spandex or Lycra: These fabrics are stretchy and are commonly used for athletic wear. While vinyl can be applied to spandex, it’s essential to ensure proper stretch and heat settings to maintain flexibility.

- Leather: Vinyl printing can also be applied to leather materials, adding a unique touch to jackets, bags, and accessories.

Keep in mind that the suitability of these methods also depends on the specific blend and quality of the fabric. Always consider the fabric’s characteristics and consult with us to determine the best method for your workwear.

Contact us now on +44 1206 670271